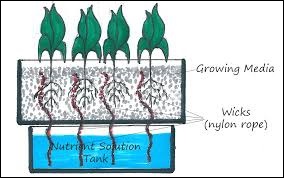

Hydroponic Wick System

A simplified example of the hydroponic wick system. A wick made of nylon rope, cotton or other material runs from a nutrient tank directly to the root mass of each individual plant. The system requires no electricity, no manual watering, and a near ideal moisture environment for a plant's roots. Image courtesy of Hydroponic Passion.

You are on Page 1 of our six page series on hydroponic wick system section. Click on any of the below pages to jump to that page.

Page 1 Page 2 Page 3 Page 4 Page 5 Page 6

Introduction

A hydroponic wick system, or wicking system, is one of the simplest growing systems available in either conventional or hydroponic systems. The general premise is that plants in a container receive water from a separate nutrient reservoir, via a wick. The wick moves the nutrient solution via capillary action, which is simply the movement of water or water-based liquids through narrow channels. We are already familiar with other forms of wicking in everyday life. For instance, towels wick water away from wet surfaces, and candle wicks move wax from the candle to the tip of the wick, where the wax then melts and burns. It turns out that plants also wick water and nutrients from the soil via their roots. All we’re doing in this hydroponic approach is using that same wicking action to deliver nutrient solution from the reservoir, to the growing medium which supports the plants’ roots.

A special note before we proceed. Many hydroponic systems are equally comfortable in a hobbyist/experimental setting, or a commercial setting. Wick systems, however, are that rare breed of hydroponics which are almost exclusively reserved for the hobbyist and/or experimental setting. For reasons we'll explore in the following sections, the wick system is best used for extremely small applications, for instance to demonstrate growth characteristics in a classroom, or to grow a few plants on a sunny porch, or possibly provide low-maintenance greens year-round. The vast majority of our comments are aimed at growers who will be using the wick system in those capacities. Commercial-scale growers who want to produce crops for sale, as quickly, consistently and cost-effectively as possible, will usually want some other system. The reasons for that will become clear as we move through this series. Just know for now that most of the following comments are aimed at the hobbyist and experimental grower group. Notes about commercial growing applications will be called out separately as they appear throughout the text.

Advantages

Wicking systems are extremely simple. Because capillary action is a normal feature of water and any water-based liquid, we don’t need to provide any power to the system to make it work. All we need to do is use a wicking material to move water from Point A (the reservoir) to Point B (the plant’s growing media). Therefore, we don’t need electrical power of any kind. Furthermore, many natural and synthetic materials can wick water and water-based liquids. Any materials which provide lots of fibers in a braided, woven or other connected orientation will have wicking properties. This includes materials like cloth and textiles, paper towels, string, thread, twine and rope, and felted materials like wool felt or synthetic poly fleece.

The other components needed in a hydroponic wicking system are equally simple:

- The container which holds the plant(s), which can be a cup, a bucket, or a plastic, rubber or metal tub.

- The container which holds the nutrient solution (ie, the reservoir), which again can be any watertight vessel.

- The plants themselves

- The growing media which holds the plant’s roots. Most growing media, by definition, also has wicking potential, so any growing media can be used in a wicking system. However, some growing media are better choices than others. We’ll cover this in more detail later in this series.

Because these components can be made of so many different materials, one of the greatest advantages of the hydroponic wicking system is that a grower can source these materials for free, or even re-purpose materials which would otherwise go to waste. For folks who are trying to build a hydroponics system on a shoestring budget (which, by the way, is another wick candidate!) it’s hard to beat this system.

Another advantage is the utter simplicity of the system. Since there are no moving parts, the system is very simple to set up and maintain. The main daily tasks are to monitor the plants for signs of disease (which we should be doing in any hydroponic system), and monitor the reservoir’s water levels. That’s it. The wick will just keep moving nutrient solution from the reservoir to the growing media as long as there is nutrient solution in contact with the wick.

A third advantage to this system is that, strictly speaking, we don’t need electricity or power of any kind for the nutrient system delivery. The capillary action of the wick will just keep moving nutrient from one place to another as long as the wick has nutrients to move. So this system is well suited to areas where electricity is expensive, unreliable, or simply unavailable.

You are on Page 1 of our six page series on hydroponic wick system section. Click on any of the below pages to jump to that page.